Table of content

***Client name and identifying details have been anonymized for confidentiality.

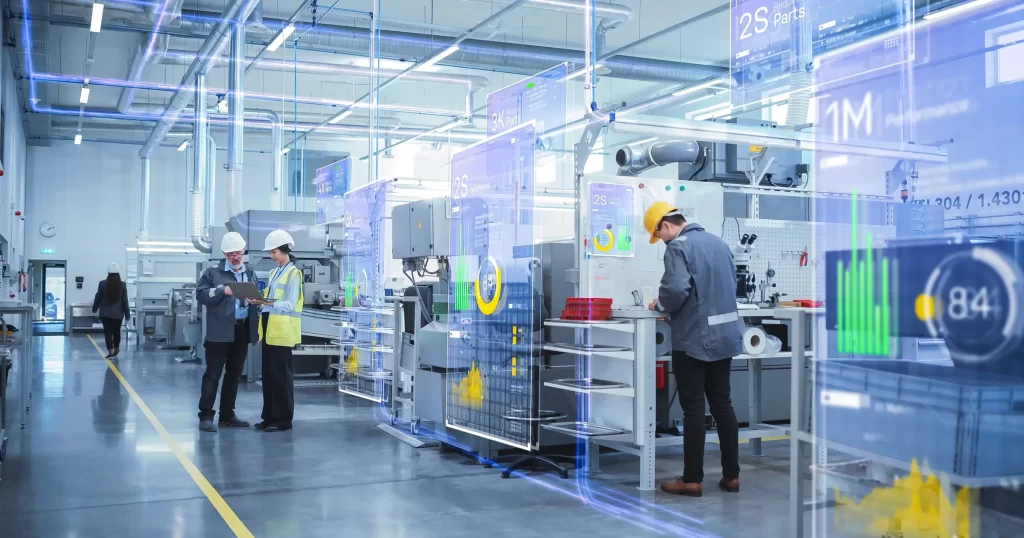

Subject: How logistics video analytics drives profitability and risk reduction in warehousing

Industry: Warehouse & Logistics

The Challenges It Faces

Operational Blind Spots in Modern Logistics: The inherent complexity of modern, high-throughout logistics facilities creates massive “blind spots” areas where operations lack real-time visibility and rely on latency-prone manual data entry. These blind spots translate directly into quantifiable business losses and safety risks.

1. Dock and Yard Management: The loading dock is critical interface between inbound/outbound transit and inventory management. When this area is managed anecdotally, the results are severe and costly:

- Yard Congestion: Inefficient staging and routing leads to trucks queuing, unnecessary idling, and a chaotic yard. This not only burn fuel and time but also increase the risk of vehicular incidents.

- Sub-optimal Resource Allocation: Managers struggle to forecast labor needs because they lack real-time, objective data on truck flow and turn-around times (TAT). This results in unnecessary overtime or conversely, docks sitting idle due to missed opportunities.

2. Workplace Safety and Compliance: In a high-traffic environment where powered industrial trucks share space with personal, safety lapses are inevitable without automated oversight. The challenges extend beyond preventing major incidents to establishing a culture of compliance:

- Inconsistent PPE: Spot checks are unreliable. Non-compliance with mandatory PPE (e.g., helmet, safety vests) is common. exposing the organization to heightened injury risk and regulatory fines.

- The Problem of Near-Misses: Many safety incidents are near-misses that go unreported. Without a system to automatically flag these events, companies miss out on valuable data that could prevent future, more serious accidents.

- Human Error and Fatigue: The combination of long hours and repetitive, high-stress tasks increases the probability of human error, especially concerning safety driving and operational procedures.

- Fire & Smoke Hazards: Warehouse often contain flammable materials and high-density storage areas where small ignition sources can escalate quickly. Manual monitoring and conventional sensors are often too slow or too limited in coverage, leading to delayed response times and potentially catastrophic losses.

3. Operational Inefficiencies: Every inefficiency is a silent cost such as a delay pallet, a misrouted forklift, a missing inventory item. Yet, most facilities operate without actionable date to identify these bottlenecks.

- Shrinkage and Security Lapses: Internal theft, product misplacement, or external intrusion are often detected too late. The challenge is monitoring vast areas 24/7 without excessive labor costs.

- Lack of Actionable Data: Traditional metrics are often lagging indicators. Managers need real-time, predictive intelligence to make corrective interventions now, not next month.

The Solutions We Deliver

CXVIEW transforms passive surveillance video historical record into an active predictive data stream by applying deep learning models to existing or new camera infrastructure, we provide the cognitive layer necessary for intelligent logistics management.

1. Optimizing Dock Management: no more guesswork, no more radio calls

- License Plate Recognition (LPR): Instantly identifies and records vehicle entry and exit.

- Automated Alerts: Sends instant notifications to managers when delays or anomalies occur.

2. Proactive Safety Monitoring and Incident Prevention: Safety is not a reaction, it’s a culture. With Ai-driven visibility, safety isn’t left to chance, it’s continuously and quietly enforced.

" alt="Retail Foot Traffic Analytics: The Foundation for Data-Driven">

" alt="Retail Foot Traffic Analytics: The Foundation for Data-Driven">

" alt="AI Video Analytics for Retail: The Gifts from Nature Retail Chain">

" alt="AI Video Analytics for Retail: The Gifts from Nature Retail Chain">

" alt="From High-Risk to High-Yield: AI Vision in Animal Feed Manufacturing">

" alt="From High-Risk to High-Yield: AI Vision in Animal Feed Manufacturing">