We deliver custom AI solution meticulously engineered for seamless integration with your existing infrastructure and legacy systems. Our approach leverages your unique operational blueprint, ensuring rapid, non-disruptive deployment and maximum ROI.

Industrial Manufacturing

Your Operation. Our Integration.

Boost manufacturing efficiency and worker safety with AI video analytics built for real-time monitoring, process optimization, and incident prevention. We deliver custom solutions designed to intergrade with existing infrastructure and align with your unique operational and business model needs.

The Challenges It Faces

/01

Workforce Safety Risk: The Unseen Threat

Traditional monitoring systems in manufacturing have critical blind spots. They fail to:

- Enforce PPE compliance

- Detect unsafe behaviors

- Identify early smoke or fire risks

- Prevent security breaches, theft, or unauthorized access

These gaps heighten operational risks, turning preventable hazards into costly incidents. The organizations face compromised safety, slower emergency response, and greater legal and reputational damage.

/02

Operational Inefficiencies: The Hidden Cost of Manual Monitoring

Manufacturers still relying on manual monitoring face rising inefficiencies and hidden costs. Human error, unbalanced workforce allocation, and lack of real-time visibility across production zones lead to:

- Operational bottlenecks that slow throughput

- Reactive decisions instead of predictive control

- Wasted labor hours and declining productivity

These inefficiencies quietly erode profit margins and limit overall performance.

/03

Data Analytics & Lagging Intelligence: The Insight Gap

Too much data. Too little insight.

Manufacturers are overwhelmed by the sheer volume of video feeds, sensor readings, and operational data generated daily. This creates a significant lag between event and awareness, leading to:

- Delayed insights

- Reactive decisions

- Missed opportunities for optimization and growth.

The net effect is intelligence that always arrives late, limiting agility and competitive edge.

Our Approach

Step 1

Assessment

We begin on-site to understand your operations, goals, and expectations, then collect and structure data from existing systems to build a strong foundation for AI deployment.

Step 2

Design

Based on operational insights, we develop a customized AI solution using advanced algorithms and models tailored to your manufacturing challenges and performance goals.

Step 3

Integration

The solution is seamlessly deployed and integrated into existing workflows, supported by comprehensive testing and validation to ensure accuracy, reliability, and scalability.

Step 4

Optimization

We empower your team through hands-on training, provide continuous technical support, and monitor system performance to drive ongoing improvement and long-term value.

The Solutions We Deliver

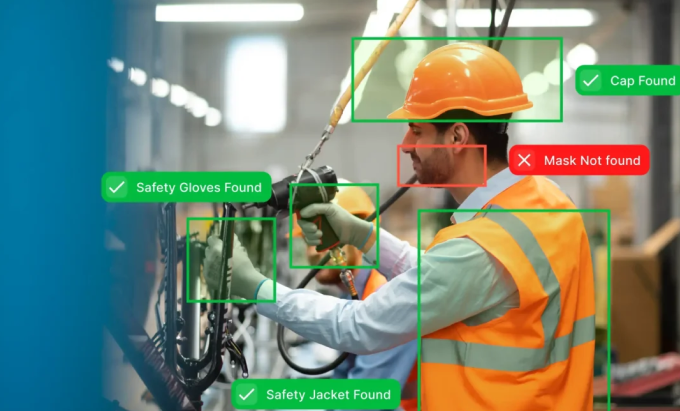

PPE Detection

Smart monitoring ensures real-time detection of missing personal protective equipment (PPE) and sends instant alerts to on-site and remote stakeholders. The system identifies absent helmets, vests, or masks, enabling immediate corrective action and reducing human oversight errors.

Tailored PPE monitoring solutions adapt to the unique safety requirements of every industry, helping workplaces prevent costly safety violations, reduce accident risks, and reinforce a culture of zero-compromise protection. Safety compliance becomes a proactive, reliable, and measurable process, safeguarding both employees and operational productivity.

Face Recognition

Fast, accurate identity verification ensures only authorized personnel access sensitive areas. The system detects and authenticates employees, visitors, and unauthorized individuals in real time, helping prevent intrusions, reduce security risks, and simplify access management.

Integrated with real-time data and intelligent access controls, the solution enhances security, improves operational efficiency, and strengthens workforce accountability across manufacturing facilities. Tailored for industrial environments, it turns access management into a proactive, reliable, and seamless process, safeguarding both personnel and operations.

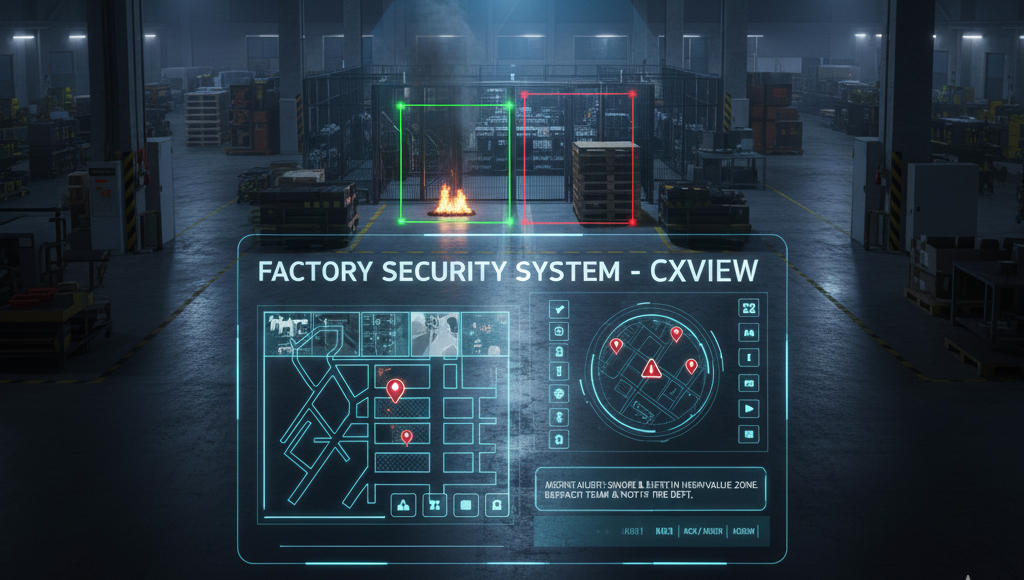

Smoke & Fire Detection

Advanced video analytics provide early-stage detection of smoke and fire, identifying hazards long before traditional sensors respond. The system continuously monitors high-risk areas such as production lines, storage rooms, and chemical handling zones, detecting even subtle signs of smoke or flames and sending instant alerts to on-site and remote teams.

Fires in these areas can lead to millions in property damage, halted production, lost inventory, and safety risks for employees. Early intervention enables immediate action, reduces downtime, and prevents costly disruptions, ensuring a safer workplace and uninterrupted operations. Tailored for industrial manufacturing, this solution delivers reliable, real-time, and actionable fire protection across all critical areas.

Intrusion & Theft Detection

AI cameras provide real-time detection of unauthorized entry and theft across factory zones. Continuous monitoring of restricted and high-value areas triggers instant alerts to on-site and remote teams the moment suspicious activity occurs.

With AI-driven situational awareness and rapid response, manufacturers can prevent losses, enhance facility security, and maintain a safe, accountable operational environment. The system turns security into a proactive, reliable, and efficient solution that protects both people and assets.

AI Vehicle Weighting System

The AI Vehicle Weighing System automates entry and exit control by capturing vehicle weight, license plates, and cargo status in real time. The system intelligently verifies whether the vehicle’s load matches recorded data, ensuring no products are left behind or removed without authorization.

By integrating visual recognition with precise weight measurement, CXVIEW enhances logistics transparency, prevents loss or fraud, and streamlines vehicle flow at the factory gate with zero manual intervention.

Smart Vision for Product Quality

CXVIEW’s Smart Vision system harnesses AI cameras to automatically inspect every product on the production line with unmatched accuracy and speed. It detects surface defects, mislabeling, color deviations, or dimensional irregularities invisible to the human eye, ensuring consistent quality, zero-defect standards, and reduced rework costs.

By integrating real-time analytics and visual intelligence, CXVIEW transforms manual inspection into a data-driven quality assurance process, enabling manufacturers to maintain brand integrity, increase yield, and elevate customer trust.

Automated Product Counting

The AI video analytics tracks and counts products on the assembly line, automatically recording the data in a centralized dashboard.

Ensures accurate inventory and production data, prevents miscounts, streamlines material management, and improves overall operational efficiency.

24/7 AI Monitoring

We turn data into decisions, monitoring into prevention, and efficiency into a competitive edge. Our solution continuously monitors factory operations, working around the clock to:

- Real-time Detection and Alerting

- Ensure Absolute Safety

- Gain Clear Overview

- Proactive Prevention

This continuous monitoring system ensures uninterrupted supervision, significantly enhances workplace safety, and drive data-informed productivity improvements across every shift.

Precision You Can Trust

Smart AI dashboard for real-time factory visibility and optimization

Real-time production monitoring

Predictive maintenance alerts

Automated quality analytics

Centralized operational control

CXVIEW Solutions Across Industries

Ms. Jennifer N.

Boutique Owner, Thao Dien, HCMCCXVIEW has transformed how we manage both security and customer experience. The People Counting feature helps us track peak hours, optimize staffing, and plan marketing campaigns more strategically. The Face Recognition system enhances safety by instantly alerting our team about blacklisted individuals or repeat offenders. The solution operates seamlessly, delivers real-time insights, and comes with exceptional technical support. Highly recommended for any modern retail business.

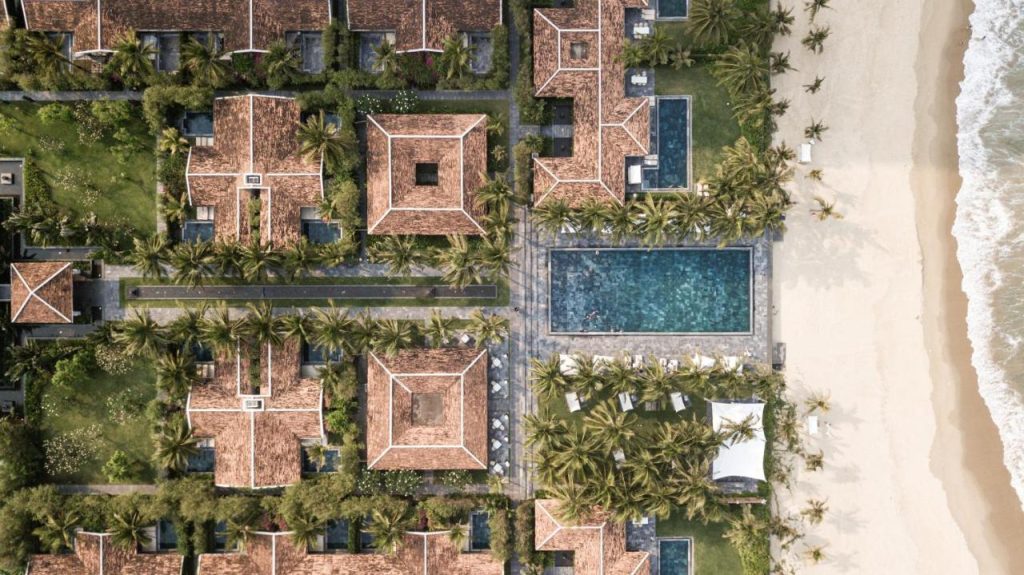

From real-time guest flow tracking to fire and intrusion alerts, CXVIEW gives us both efficiency and peace of mind, a perfect fit for hospitality operations.

As the owner of several convenience stores, I needed a solution to manage security, reduce shrinkage, and improve staff efficiency across locations, and CXVIEW delivered. Their end-to-end AI surveillance ecosystem helps me manage multiple stores from different locations with ease, from real-time security alerts to customer flow tracking. It’s a smart, reliable system that gives us complete visibility and control 24/7.

In our wood production facilities, CXVIEW plays a key role in both safety and quality control. Wall Climbing Detection secures our perimeter, while Smoke & Fire Detection provides early warnings in high-risk areas. Product Color Check ensures consistent finishing quality, and PPE Recognition keeps our workers compliant. The system runs seamlessly and integrates perfectly into our operations.

Our Client feedback